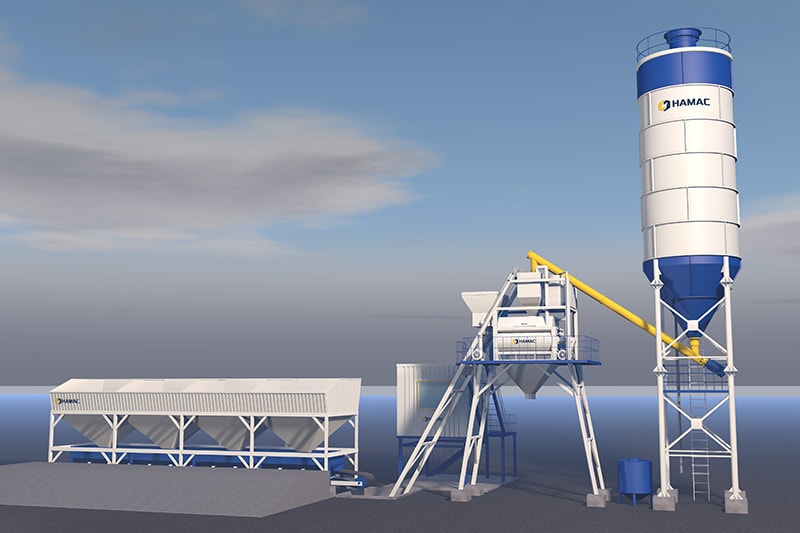

Enhance Your Concrete Production with Hamac’s Stationary Batching Plants

In the realm of large-scale construction, efficiency, reliability, and precision are paramount. Hamac’s stationary concrete batching plants are engineered to meet these demands, offering robust solutions for projects requiring consistent and high-quality concrete output.

👉 Discover Hamac’s Stationary Concrete Batching Plants

👉 Discover Hamac’s Stationary Concrete Batching Plants

🏗️ What Are Stationary Concrete Batching Plants?

Stationary concrete batching plants are permanent installations designed for the mass production of concrete. They are ideal for projects where the construction site remains in one location for an extended period, such as:

- Commercial building projects

- Infrastructure developments

- Precast concrete production

These plants ensure a continuous supply of concrete, minimizing delays and enhancing project timelines.

These plants ensure a continuous supply of concrete, minimizing delays and enhancing project timelines.

⚙️ Key Features and Advantages

🔧 High-Quality Components

Hamac utilizes renowned international brands to ensure durability and performance:

Hamac utilizes renowned international brands to ensure durability and performance:

- Pneumatic cylinders from Japan SMC

- Vibrators and butterfly valves from Italy WAM

- Air compressors, water pumps, and electrical components from top-tier suppliers

- SICOMA concrete mixers for efficient mixing

📊 Advanced Control Systems

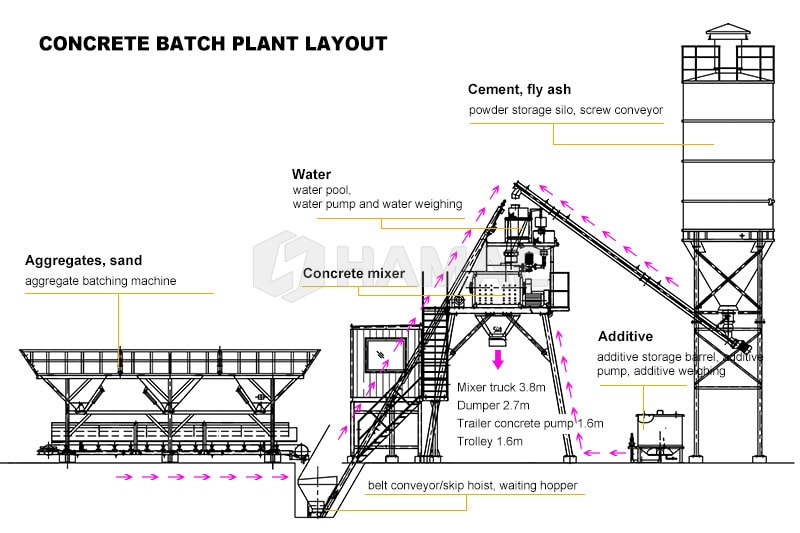

The plants are equipped with fully automatic PLC control systems, allowing for:

- Precise weighing of aggregates, cement, water, and additives

- Automated mixing cycles

- Real-time monitoring and adjustments

🛠️ Modular Design

The modular structure facilitates:

- Easy transportation and installation

- Flexible configuration to meet specific project requirements

- Simplified maintenance and operation

📐 Technical Specifications

| Model | Capacity (m³/h) | Mixer Model | Batching System | Discharging Height (mm) | Total Power (kW) |

|---|---|---|---|---|---|

| HZS25 | 25 | JS500 | PLD1200 | 4100 | 50 |

| HZS35 | 35 | JS750 | PLD1200 | 4100 | 61 |

| HZS50 | 50 | JS1000 | PLD1600 | 4100 | 84 |

| HZS60 | 60 | JS1000 | PLD1600 | 4100 | 106 |

| HZS75 | 75 | JS1500 | PLD2400 | 4100 | 127 |

| HZS90 | 90 | JS1500 | PLD2400 | 4100 | 145 |

| HZS120 | 120 | JS2000 | PLD3200 | 4100 | 175 |

| HZS180 | 180 | JS3000 | PLD4800 | 4100 | 215 |

Note: Specifications may vary based on customization.

🌍 Applications

Hamac’s stationary batching plants are suitable for:

- Ready-mix concrete production

- Precast concrete manufacturing

- Large-scale infrastructure projects

- Long-term construction sites

Their reliability and efficiency make them a preferred choice for contractors worldwide.

Their reliability and efficiency make them a preferred choice for contractors worldwide.

✅ Why Choose Hamac?

- Global Reach: Hamac’s equipment is exported to various countries, meeting international standards.

- Customization: Tailored solutions to fit specific project needs.

- After-Sales Support: Comprehensive support and training services.

- Quality Assurance: Use of high-quality components ensures longevity and performance.

👉 Learn More About Hamac’s Stationary Concrete Batching Plants

🔚 Conclusion

Investing in Hamac’s stationary concrete batching plants means committing to quality, efficiency, and reliability. Whether you’re undertaking a massive infrastructure project or setting up a precast concrete facility, Hamac provides the solutions to keep your operations running smoothly.

Ready to elevate your concrete production capabilities?

Comments

No comments yet. Be the first to react!