Maximize Output and Flexibility with Dry Batch Concrete Batching Plants

In large-scale infrastructure and commercial construction, time and efficiency are everything. One of the most cost-effective and high-output solutions in concrete production is the dry batch concrete batching plant. With a simplified process and faster discharge times, this system is ideal for contractors aiming to boost productivity without compromising quality.

👉 Explore Hamac’s dry batch concrete batching plants

🏗️ What Is a Dry Batch Concrete Batching Plant?

Unlike wet mix plants, a dry batch concrete plant doesn’t mix water into the concrete components on site. Instead, it prepares and loads dry ingredients — such as cement, sand, and aggregates — into a mixer truck. The mixing process is then completed in transit during delivery.

This makes it especially useful for projects that:

-

Require fast output of concrete materials

-

Have short transportation distances

-

Need flexibility in concrete mix design on site

⚙️ How It Works

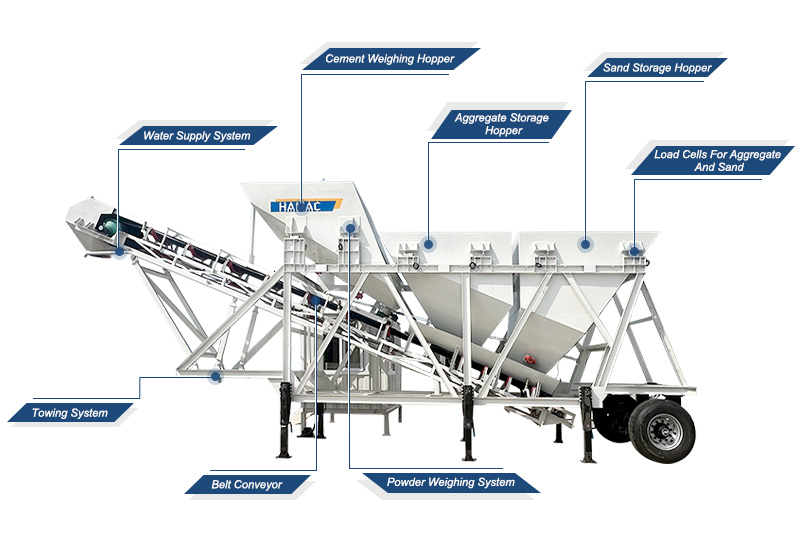

A dry batch plant includes:

-

Cement silo

-

Aggregate batching machine

-

Weighing system for precise ingredient proportions

-

Discharge system for rapid truck loading

-

Control panel for automated batch commands

The materials are measured, loaded, and discharged into transit mixers, which complete the mixing process while driving to the jobsite.

Learn more:

👉 Hamac dry batching plant product page

🌟 Key Advantages

⏱ Higher Productivity

Dry batching enables quick loading and faster batch cycles, often with fewer moving parts than wet systems.

💧 Lower Water Usage

No water is used during batching — saving water and allowing precise moisture control at the jobsite.

🔧 Lower Maintenance

Fewer internal mixers and moving parts reduce maintenance costs and machine downtime.

🚛 Transportation-Ready

The concrete mixing process happens inside the transit mixer, reducing on-site labor and simplifying logistics.

🔍 Technical Features to Consider

| Feature | Details |

|---|---|

| Rated Output | 60 – 120 m³/h |

| Mixing Type | Transit mixer-based |

| Control System | Fully automatic PLC |

| Aggregate Bins | Multiple hoppers with weighing |

| Cement Silo | 50T / 100T options |

Ideal for bridge projects, road paving, and commercial foundations where speed is critical.

✅ Ideal Applications

Dry batch plants are perfect for:

-

Urban road construction

-

Large concrete supply networks

-

Commercial buildings

-

Precast concrete plants

-

Highway and bridge projects

With the right transit mixers, you can scale production up or down depending on your project’s size and timeline.

🌍 Environmental and Economic Benefits

-

Lower energy usage (no in-plant mixing)

-

Reduced cement waste with accurate weighing

-

Modular design for easier relocation

-

Less water consumption and minimal spillage

Want to cut cost and improve site logistics?

📦 Why Choose Hamac?

Hamac offers durable, high-capacity dry batch concrete batching plants engineered for high-performance projects. With a focus on automation, energy efficiency, and long-term stability, Hamac’s solutions are trusted by contractors worldwide.

Key advantages:

-

Global shipping

-

Full technical support

-

OEM customization available

-

Easy installation and operation

🔗 See Hamac dry batching plant options

🔚 Final Thoughts

If you’re looking to reduce operational costs, accelerate concrete delivery, and optimize your batching workflow, a dry batch concrete batching plant is the ideal investment. Its streamlined design, low maintenance needs, and compatibility with transit mixers make it perfect for demanding construction timelines.

Ready to level up your concrete production?

👉 Click here to explore Hamac’s dry batch solutions

Comments

No comments yet. Be the first to react!